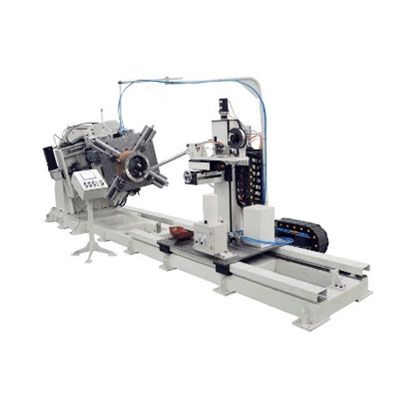

STRIP CLADDING DEVICE

STRIP CLADDING DEVICE

The Strip Cladding Device is a precision machine designed for applying cladding in the form of metal strips onto pipes, tubes, or flat surfaces. This method is especially effective for thick, wear-resistant, or corrosion-resistant layers and is widely used in chemical, petrochemical, power generation, and industrial piping applications.

The device ensures uniform deposition, precise alignment of cladding strips, and high bonding quality with minimal manual intervention. It is compatible with MIG, TIG, or Submerged Arc Welding (SAW) processes, depending on the material and application requirements. Automated strip feeding and torch movement significantly improve productivity and repeatability.

Key Features

- The installation is for internal vertical hole or valve line automatic cladding. Cold TIG/hot wire TIG welding processes.

- Provides high-quality, low-dilution cladding with excellent metallurgical properties.

- Servo or hydraulic-controlled torch travel for precise deposition along the workpiece.

- User-friendly interface for programming parameters, monitoring deposition, and adjusting in real-time.

SPECIFICATION

Tiny strip cladding head - KSC-30

- Strip type: 30mm wide, 0.4/0.5mm thickness

- Clad work: Outer cladding: OD>220mm

- Inner cladding: ID(after weld)>350mm(longitudinal) ID(after weld)>360mm(circum)

- Preheat temperature: above 250℃(forced water)

Medium strip cladding head - KSC-60

- Strip type: 30mm wide, 0.4/0.5mm thickness

- Clad work: Outer cladding: OD>220mm

- Inner cladding: ID(after weld)>350mm(longitudinal) ID(after weld)>360mm(circum)

- Preheat temperature: above 250℃(forced water)

Conventional strip cladding head - KSC-90

- Strip type: 30~120mm wide, 0.4/0.5mm thickness

- Clad work: above ɸ800mm

- Preheat temperature: above 100℃(forced water)

- Magnetic control should be used when above 60mm strip

Frequently Asked Questions

What you should know

What types of welding services do you offer?

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts. Separated they live in.

Is your welding staff certified?

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts. Separated they live in.

How do you ensure welding safety?

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts. Separated they live in.

Can you handle on-site welding A projects?

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts. Separated they live in.

What materials can you weld?

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts. Separated they live in.

How do you determine the cost of a welding project?

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts. Separated they live in.