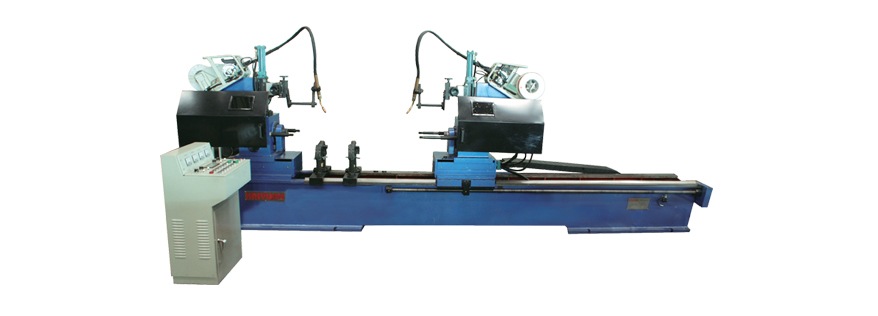

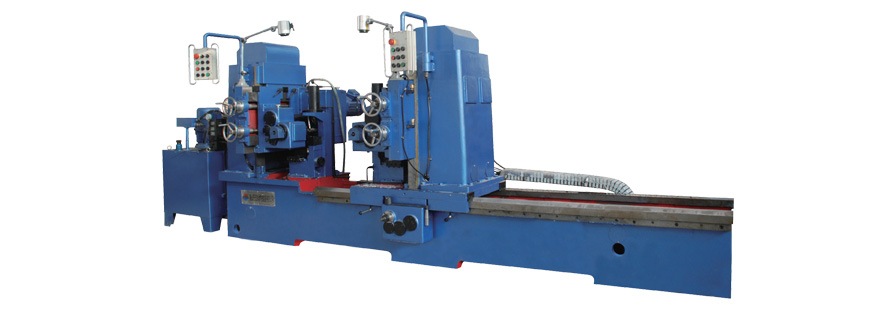

AUTOMATIC END HOLE TURNING

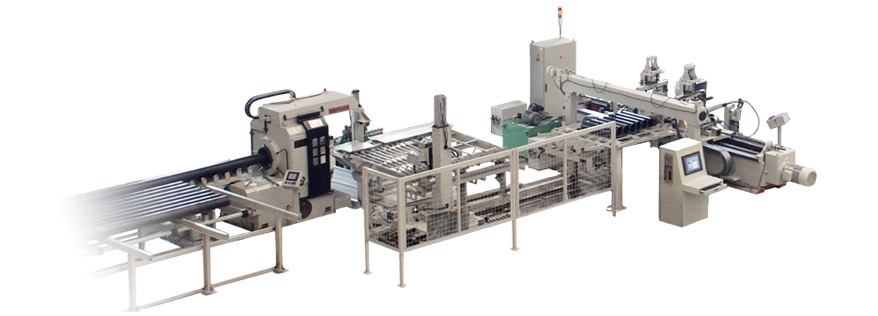

AUTOMATIC CUTTING & BEVELLING

The Automatic End Hole Turning Machine is a precision machining system designed for internal turning (boring) and finishing of holes at the ends of workpieces—such as pipes, shafts, cylindrical parts, and casings. It automates the process of turning the internal surface of an end bore to strict tolerances, ensuring consistent surface finish, dimensional accuracy, and concentricity.

This machine is ideal for high-volume manufacturing or applications where manual boring would be slow, inconsistent, or impractical. It combines robust mechanical design, CNC or servo control, tooling systems, and often in-process measurement to deliver reliable results with minimal operator intervention.

Key Features

- Used for the synchronous processing of the spigot at both ends of the steel pipe.

- The vertical and horizontal feeding of the tool is driven by hydraulic pressure, which produces smooth feeding with high precision.

- The workpiece’s clamping, positioning, tool feeding and withdrawing are automatically done in sequence with high productive efficiency.

- Safety & Protection Features — overcurrent protection, overload alarms, tool breakage detection, interlocks

SPECIFICATION

| Model | QJKA-159-2.2D-Z | QJKA-219-2.6D-Z |

|---|---|---|

| Spindle center height of the machine tool | 900 mm | 900 mm |

| Outer dia. of steel pipe | Ø76–Ø159 mm | Ø76–Ø219 mm |

| Length of steel pipe | 200–2200 mm | 200–2600 mm |

| Spigot depth | 0–70 mm | 0–70 mm |

| Moving speed of the slide | 2000 mm/min | 2000 mm/min |

| Spindle speed | 350 r/min, 500 r/min | 250 r/min, 390 r/min |

| Feeding speed | Hydraulic stepless adjustable | Hydraulic stepless adjustable |

| Cutting depth | 0–3 mm | 0–3 mm |

| Toolholder axial feeding graduate | 0.05 mm | 0.05 mm |

| Toolholder axial back-off repeated positioning precision | 0.05 mm | 0.05 mm |

| Main driving motor | 11 kW 1450 r/min | 11 kW 1450 r/min |

| Workpiece clamping motor | 4 kW 1450 r/min | 4 kW 1450 r/min |

| Hydraulic system pressure | 2.5–4 mPa | 2.5–4 mPa |

| Flow | 25 L/min | 25 L/min |

| Dimension (L×W×H) | 5334×1120×1200 mm | 5734×1120×1200 mm |

| Weight | 5500 kg | 5800 kg |

| Processing Precision | ||

| Diameter tolerance of the spigots at both ends | IT8 | IT8 |

| Roughness of the cutting surface Ra | 6.3–3.2 μm | 6.3–3.2 μm |

| Spacing tolerance of the spigots at both ends | ≤0.2 mm | ≤0.2 mm |

| Model | QJKA-159-2.2D-Z | QJKA-219-2.6D-Z |

|---|---|---|

| Spindle center height of the machine tool | 900 mm | 900 mm |

| Outer dia. of steel pipe | Ø76–Ø159 mm | Ø76–Ø219 mm |

| Length of steel pipe | 200–2200 mm | 200–2600 mm |

| Spigot depth | 0–70 mm | 0–70 mm |

| Moving speed of the slide | 2000 mm/min | 2000 mm/min |

| Spindle speed | 350 r/min, 500 r/min | 250 r/min, 390 r/min |

| Feeding speed | Hydraulic stepless adjustable | Hydraulic stepless adjustable |

| Cutting depth | 0–3 mm | 0–3 mm |

| Toolholder axial feeding graduate | 0.05 mm | 0.05 mm |

| Toolholder axial back-off repeated positioning precision | 0.05 mm | 0.05 mm |

| Main driving motor | 11 kW 1450 r/min | 11 kW 1450 r/min |

| Workpiece clamping motor | 4 kW 1450 r/min | 4 kW 1450 r/min |

| Hydraulic system pressure | 2.5–4 mPa | 2.5–4 mPa |

| Flow | 25 L/min | 25 L/min |

| Dimension (L×W×H) | 5334×1120×1200 mm | 5734×1120×1200 mm |

| Weight | 5500 kg | 5800 kg |

| Processing Precision + | ||

| Diameter tolerance of the spigots at both ends | IT8 | IT8 |

| Roughness of the cutting surface Ra | 6.3–3.2 μm | 6.3–3.2 μm |

| Spacing tolerance of the spigots at both ends | ≤0.2 mm | ≤0.2 mm |

Frequently Asked Questions

What you should know

What types of welding services do you offer?

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts. Separated they live in.

Is your welding staff certified?

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts. Separated they live in.

How do you ensure welding safety?

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts. Separated they live in.

Can you handle on-site welding A projects?

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts. Separated they live in.

What materials can you weld?

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts. Separated they live in.

How do you determine the cost of a welding project?

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts. Separated they live in.