NARROW GAP SUBMERGED ARC WELDING

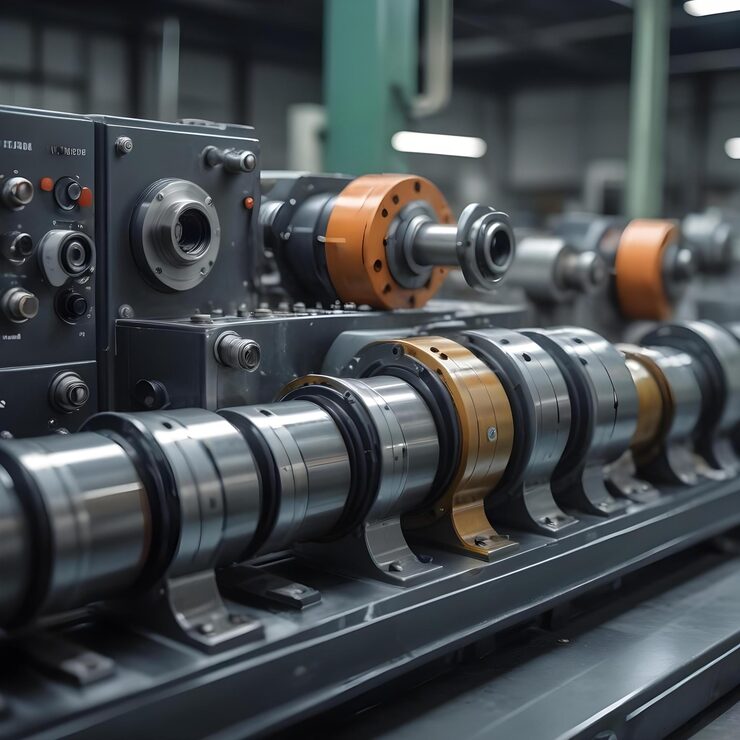

NARROW GAP SAW

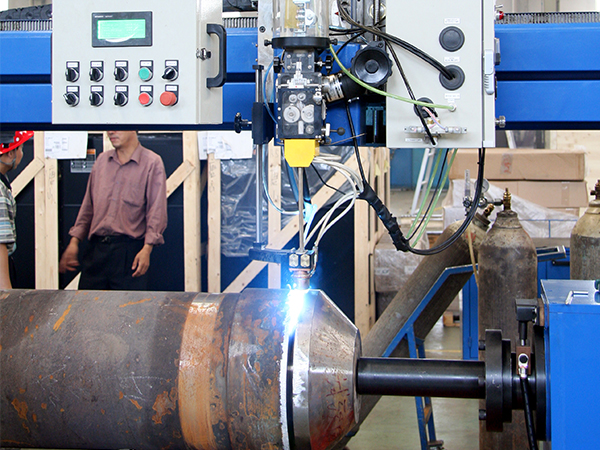

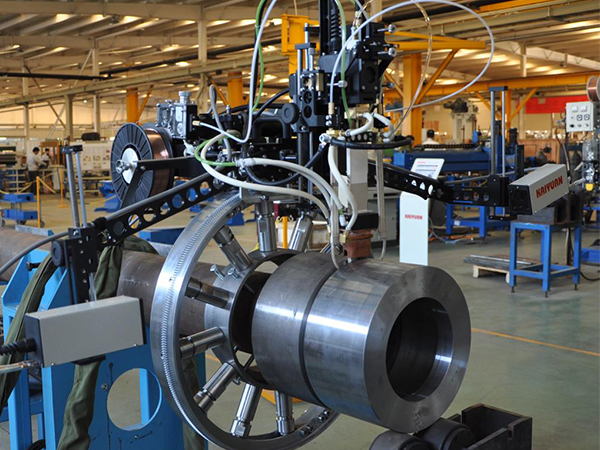

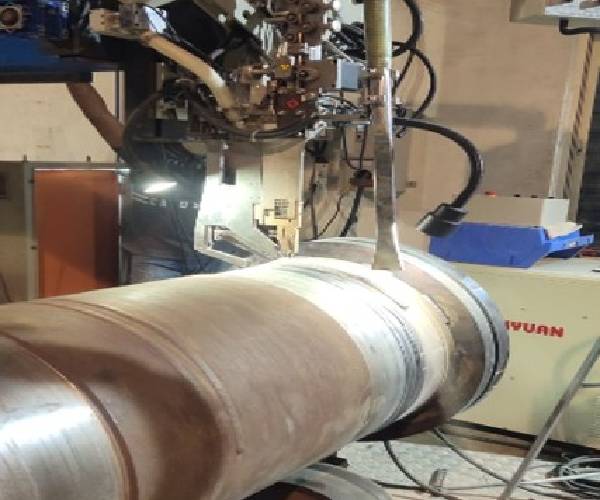

Narrow Gap Submerged Arc Welding (SAW) is a high-efficiency welding process specifically designed for joining thick materials using a reduced groove width. Unlike conventional submerged arc welding, which uses a wider groove, narrow gap SAW employs a nearly parallel or V-shaped groove with a small root opening, allowing deep penetration with fewer passes. This method minimizes filler metal usage, reduces welding time, and produces high-quality welds for heavy-duty applications.

This technique is particularly valuable in industries where precision, structural integrity, and cost-effectiveness are critical. By limiting the groove width, heat input is controlled, significantly reducing thermal distortion and preserving the mechanical properties of the base material. Narrow gap SAW also ensures uniform weld deposition, excellent root penetration, and consistent metallurgical properties throughout the joint, making it suitable for thick steel plates and alloy materials.

Key Features

- Oscillating tip, left-mid-right three position welding position, oscillating assembly is stable and reliable.

- Chromium Zirconium Copper contact tip, alloy copper material torch soft connection with good conductive, those can increase life span.

- Torch body is made of stainless steel and plasma paint technology.

- Automatic flux feeding and recovery and sensors to sense sidewall variations.

SPECIFICATION

| Max. Weld Thickness | 400 mm |

|---|---|

| Groove Angle | 1° – 2° |

| Groove Width | 18 – 30 mm (18 – 22 mm at bottom) |

| Pass No. per Layer | Two passes (One pass at first layer) |

| Wire Diameter | 3.0 / 4.0 mm |

| Wire Feed Speed | 60 – 180 mm/min |

| Deposition Speed | 5 – 10 kg/h |

| Torch Oscillating Range | ≤ ±3.5° |

| Torch Oscillating Precision | ≤ ±0.5° |

| Horizontal Tracking Precision | ≤ ±0.2 mm |

| Vertical Tracking Precision | ≤ ±0.5 mm |

| Cross Slide Strokes | 300 × 400 mm |

| Highest Heated Temperature | 350℃ |

| Min. Diameter for Internal Welding | 1500 mm |

Related Products

INDUSTRY & APPLICATION

PEB & INFRASTRUCTURE

IDLER ROLLER MANUFACTURING

RAILWAY GIRDER

PRESSURE VESSELS

SHEET METAL & AUTOMOBILE

SHIP BUILDING

Frequently Asked Questions

What you should know

What types of welding services do you offer?

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts. Separated they live in.

Is your welding staff certified?

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts. Separated they live in.

How do you ensure welding safety?

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts. Separated they live in.

Can you handle on-site welding A projects?

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts. Separated they live in.

What materials can you weld?

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts. Separated they live in.

How do you determine the cost of a welding project?

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts. Separated they live in.