SHAFT MILLING & GROOVING

SHAFT MILLING & GROOVING

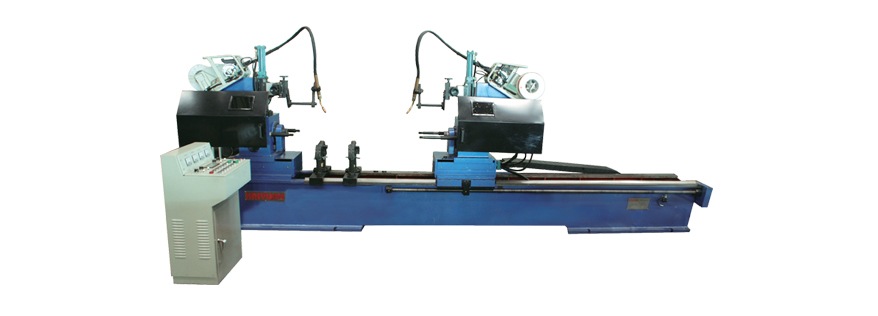

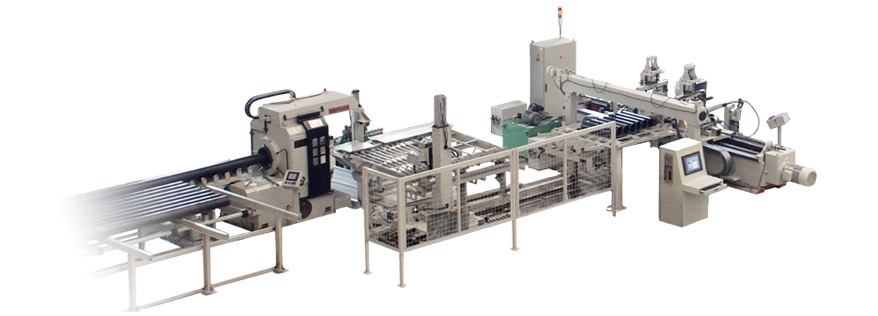

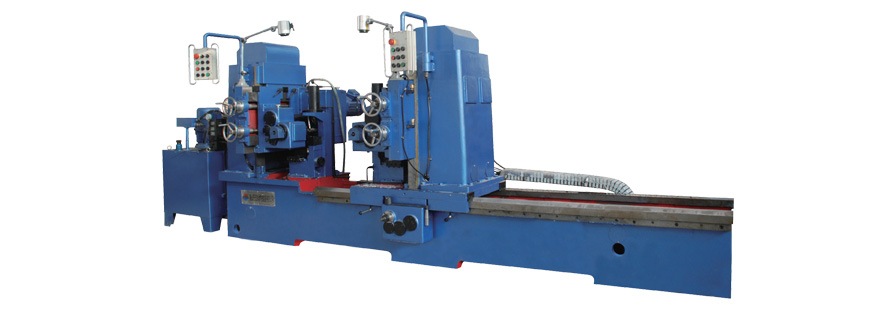

The Shaft Milling & Grooving Machine is a precision industrial solution designed for simultaneous machining of shafts, including flat surfaces, grooves, and keyways at both ends of cylindrical workpieces. Ideal for heavy-duty manufacturing and repair operations, this machine ensures high precision, uniformity, and repeatability across multiple shafts, reducing manual effort and production time.

Equipped with multiple milling heads and synchronized grooving devices, it allows simultaneous cutting on opposite ends, guaranteeing symmetrical results. The hydraulic clamping and positioning system ensures smooth tool feed, accurate alignment, and stable operation for materials like carbon steel, alloy steel, or stainless steel.

This system is widely used in idler roller production, conveyor components, shafts for industrial machinery, and automotive applications, providing consistent quality and enhanced productivity in high-volume operations.

Key Features

- Used for the synchronous processing for the flat and groove at both ends of the roller.

- Four sets of milling devices work simultaneously to guarantee the symmetry of the flat and groove of the roller shaft.

- The clamping, positioning and tool feeding are driven by hydraulic system, which enables the tool feeding smooth and the processing is highly precise.

- Hydraulic or servo-controlled tool feeding allows fine adjustment for depth and width of grooves or flats.

SPECIFICATION

| Model | QZ36-5×270 |

|---|---|

| Spindle Speed | 600, 800, 1200 r/min |

| Roller Axle Diameter | Ø20–Ø50 mm |

| Roller Axle Length | 235–2700 mm |

| Flat and Groove Width | 6–45 mm |

| Milling Depth | 0–5 mm |

| Spindle Motor | 3 kW × 2 (set) |

| Pump Motor | 5.5 kW |

| Hydraulic System Pressure | 1.5–4 MPa |

| Hydraulic System Flow | 31 L/min |

| Cooling Pump Motor | 125 W × 2 (set) |

| Dimension (L × W × H) | 7000 × 1500 × 1850 mm |

| Weight | 6600 kg |

Frequently Asked Questions

What you should know

What types of welding services do you offer?

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts. Separated they live in.

Is your welding staff certified?

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts. Separated they live in.

How do you ensure welding safety?

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts. Separated they live in.

Can you handle on-site welding A projects?

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts. Separated they live in.

What materials can you weld?

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts. Separated they live in.

How do you determine the cost of a welding project?

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts. Separated they live in.